Strategy

- Research and development of sustainable material innovation

• Develop recycled plastic pellets to promote the use of environmentally friendly materials

• Use less material for better product efficiency - Manufacturing process improvement

- Create innovation networks

• Collaborate with stakeholders to develop products that meet consumer expectations

• Use less material for better product efficiency - Design for recycling

Product and Service Development

The Company places great importance and attention on the production process to ensure quality products that meet standards seriously, by complying with customer requirements and international standards, including monitoring and evaluation for continuous improvement and development. The Company has prepared customer satisfaction surveys, sending them to all customers for satisfaction assessment to build confidence that every product manufactured by the Company meets international standards.

When the Company receives raw materials from selected suppliers, they enter the standardized raw material inspection process, performed by expert staff every time before raw materials enter the production process. Within the production process, the Company assigns expert staff to inspect product quality during production at every step, using sensory inspection, equipment inspection, and laboratory methods such as color values, thickness, image position, film tensile strength, and odor etc. When products are completed, the Company also has a final inspection process before shipping products to customers. This serves as a guideline for improving product quality, production processes, and services to achieve efficiency and continuous development for the Company's business sustainability, and to understand the Company's strengths and improvement opportunities from the customer's perspective. The Company has achieved and shows an increasing trend every year.

|

Objectives |

Operations |

Results |

|

Mono-material product sales proportion of at least 2% of total product sales proportion |

Set sub-product targets, monitor sales monthly to ensure sales meet targets, and hold meetings to track and find solutions if sales are below set targets |

Product sales achieved 2% of total product sales proportion, or increased 2-fold from last year |

|

Implement various innovation projects in the production process to reduce production costs by 19 million baht |

Have each department create production process innovations in their respective areas, with a central committee established to evaluate and monitor performance |

Reduced costs by 203% of the set target due to decreased production activities. However, other alternative measures were implemented as replacements |

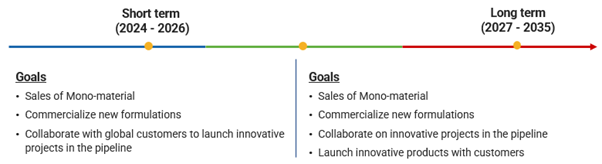

Research and Development and Innovation Business Development Policy

The Company places importance on and continuously develops research and development innovation to meet stakeholder needs and be ready to accommodate economic, social, and environmental changes, which leads to increased opportunities and competitive capabilities. The Company has departments responsible for overseeing and managing knowledge directly related to research, development, and innovation to ensure the Company's research and innovation development is sustainable, efficient, and creates maximum benefits for the Company and stakeholders. Therefore, research and development policies have been established, focusing on incorporating more recycled raw materials into products and increasing the variety of products that can contain more recycled raw materials to meet the ever-changing market demands.

The Company conducts relevant market research to clearly identify market needs, has research teams that develop materials and production formulas to increase the amount of recycled raw materials in products, and has design and product development teams to develop sample products for market testing. The Company therefore has high competitive capabilities and can sustainably lead the packaging market. The Company's research and innovation management consists of strategic planning, goal setting, and defining success indicators to serve as a framework for research and innovation development operations aligned with the organization's main objectives, including plans such as production process development, material development, product development, intellectual property management, joint ventures with external agencies in both public and private sectors to enhance organizational capabilities, as well as other supporting activities.

Over the past several years, the Company has recognized the rapidly intensifying and continuous environmental awareness trend. The Company has implemented various measures to lay the foundation for dealing with such trends, as follows:

- Establishment of the Circular Economy unit initiated in 2022, under the Marketing department, with the main responsibility of driving concrete circular economy operations, including researching and developing circular economy-related innovations to focus on developing new products aligned with such concepts.

- Appointment of the Organizational Circular Economy Management System Working Group to formulate circular economy policies and apply them within the organization to have clear working frameworks in the same direction throughout the group of companies.

- The "Von" Project was established to raise recycling awareness within the Company and expand to external agencies. The Von Project accepts donations of clean and dry flexible plastic waste from consumers and recycles them according to circular economy principles to reduce plastic waste contamination in the environment. Additionally, it collaborates with various organizations to create awareness about the importance of recycling and circular economy principles.

Examples of Business Innovation for Society and/or Environment

Recycled Material Innovation from Household Plastic Waste to Circular Plastic Pallets in Warehouses

This is a project operated under the circular economy framework, with the objective of creating value and adding value to flexible plastic waste generated at the household level through development and processing into high-quality recycled materials that can be applied in the plastic pallet manufacturing industry, which is essential equipment used for efficient storage and transportation of goods in industrial warehouses. The environmental benefits of this innovation include reducing plastic waste leakage into the environment, increasing the proportion of recycled materials used in the production process to reduce dependence on natural resources, and reducing greenhouse gas emissions throughout the product lifecycle. In addition to environmental benefits, this project also plays an important role in creating new business opportunities aligned with current global economic trends toward a green economy for the Company and stakeholders throughout the supply chain, leading to stable and sustainable long-term business growth.

Quantitative Benefits to Business

The innovation can be commercially scaled by generating revenue from sales of PCR-HD plastic pellets, pallet injection grade.

Quantitative Benefits to Society

Promote responsible consumption through awareness and understanding creation by the Von Project to encourage household waste separation at the source.

Environmental Benefits

- Reduced PE flexible plastic waste from households by more than 19.7 tons, equivalent to more than 5.9 million shopping bags

- Reduced greenhouse gas emissions from PCR-HD recycled plastic pellet production, pallet injection grade, compared to virgin raw material pellet production by more than 303 tons of CO2 equivalent

- Reduced greenhouse gas emissions throughout the lifecycle of PCR plastic pallet products by more than 332 tons of CO2 equivalent